Why iLenSys Obsolescence Manager for Engineering and R&D?

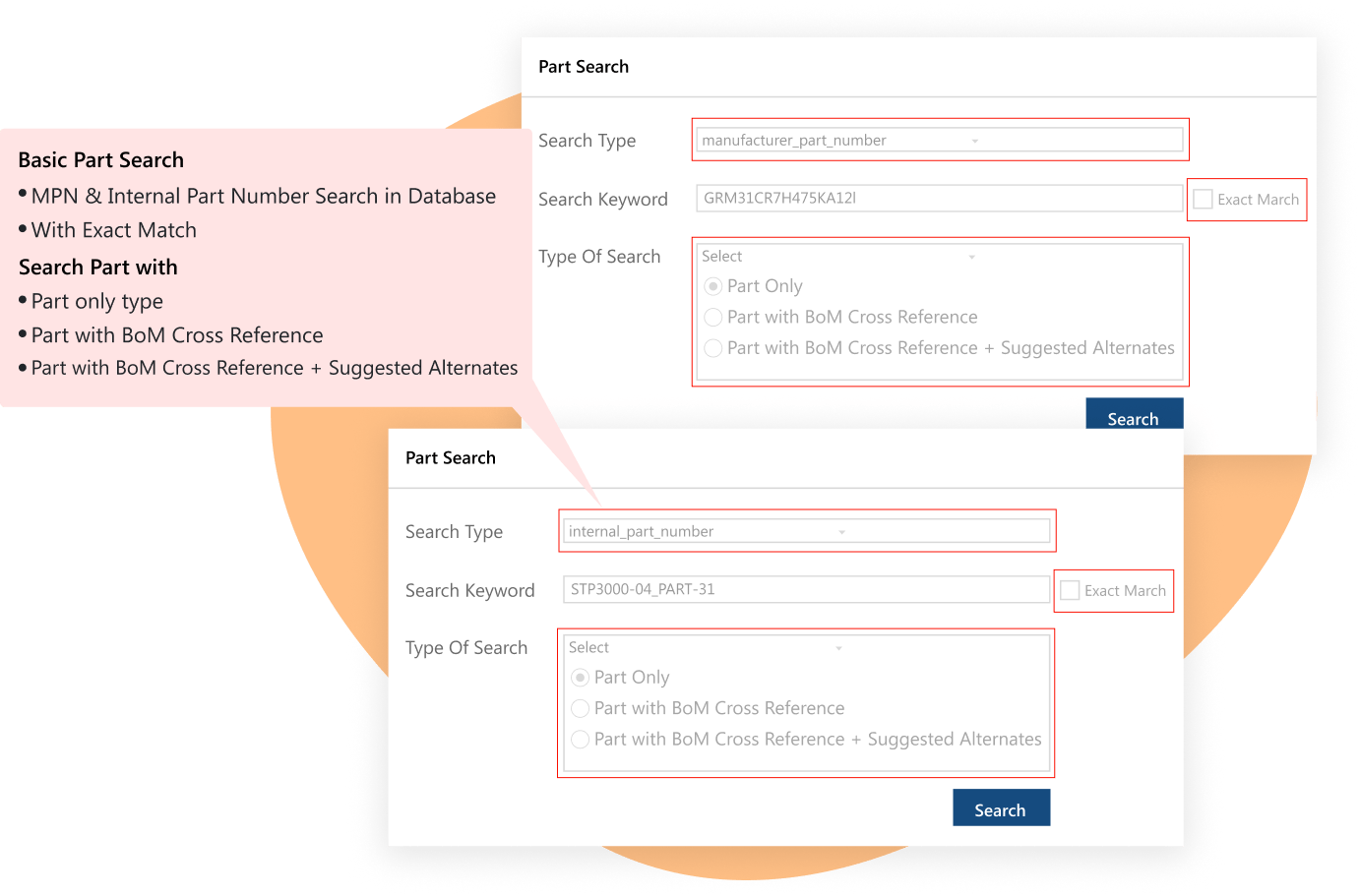

For new product development, Engineering and R&D professionals must ensure that all components and materials

used are reliable, available, and compliant with relevant regulations and standards.

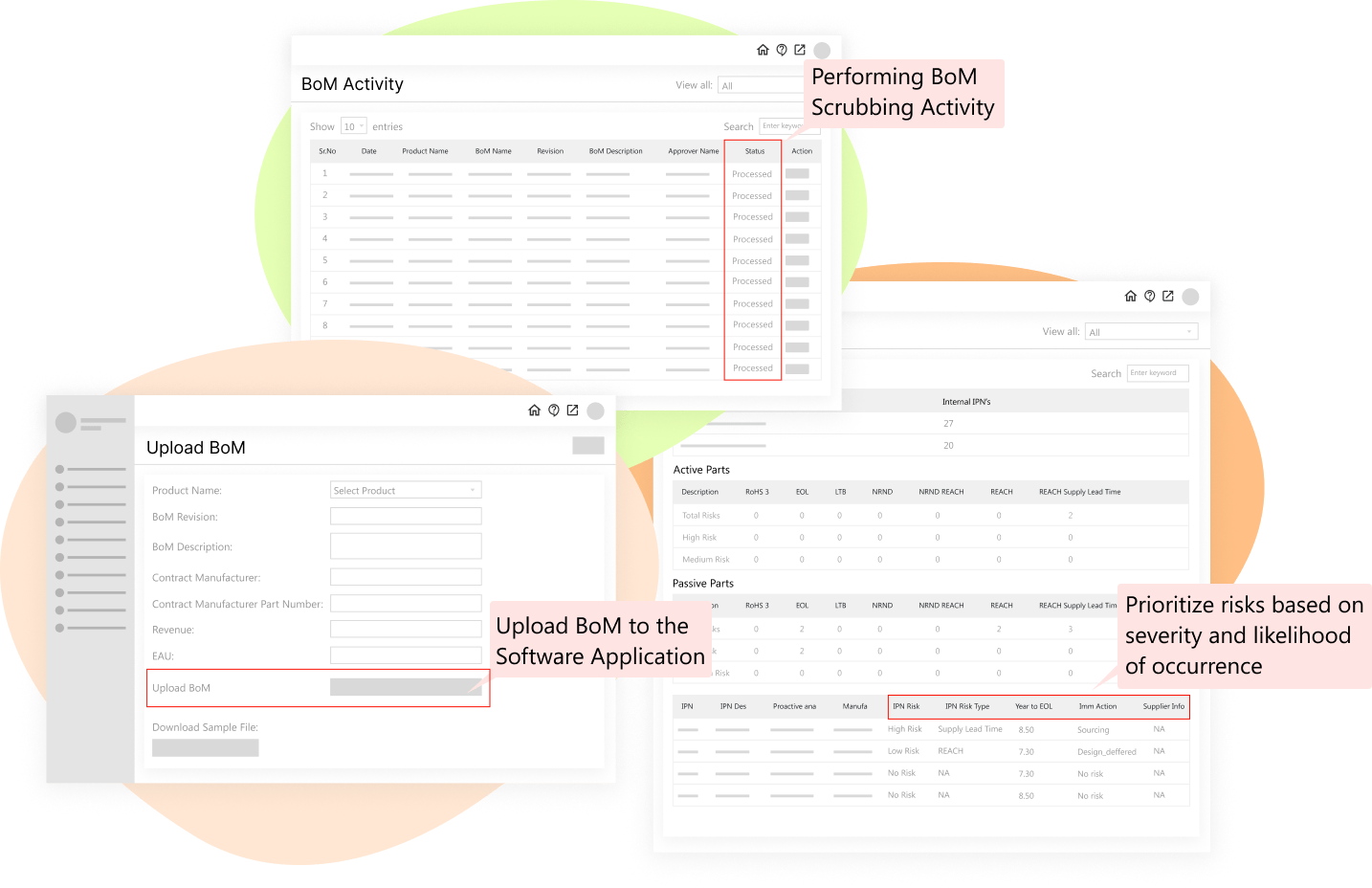

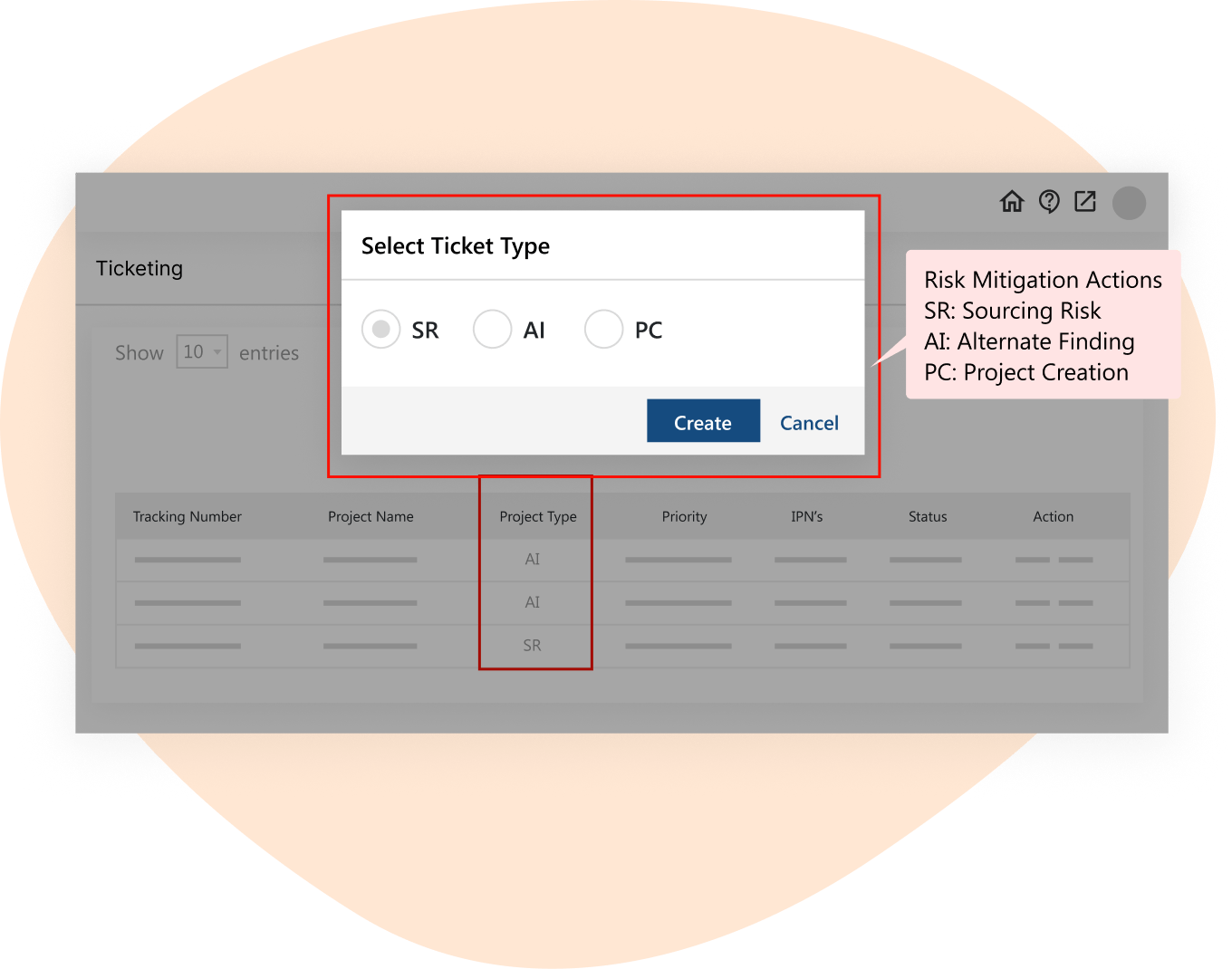

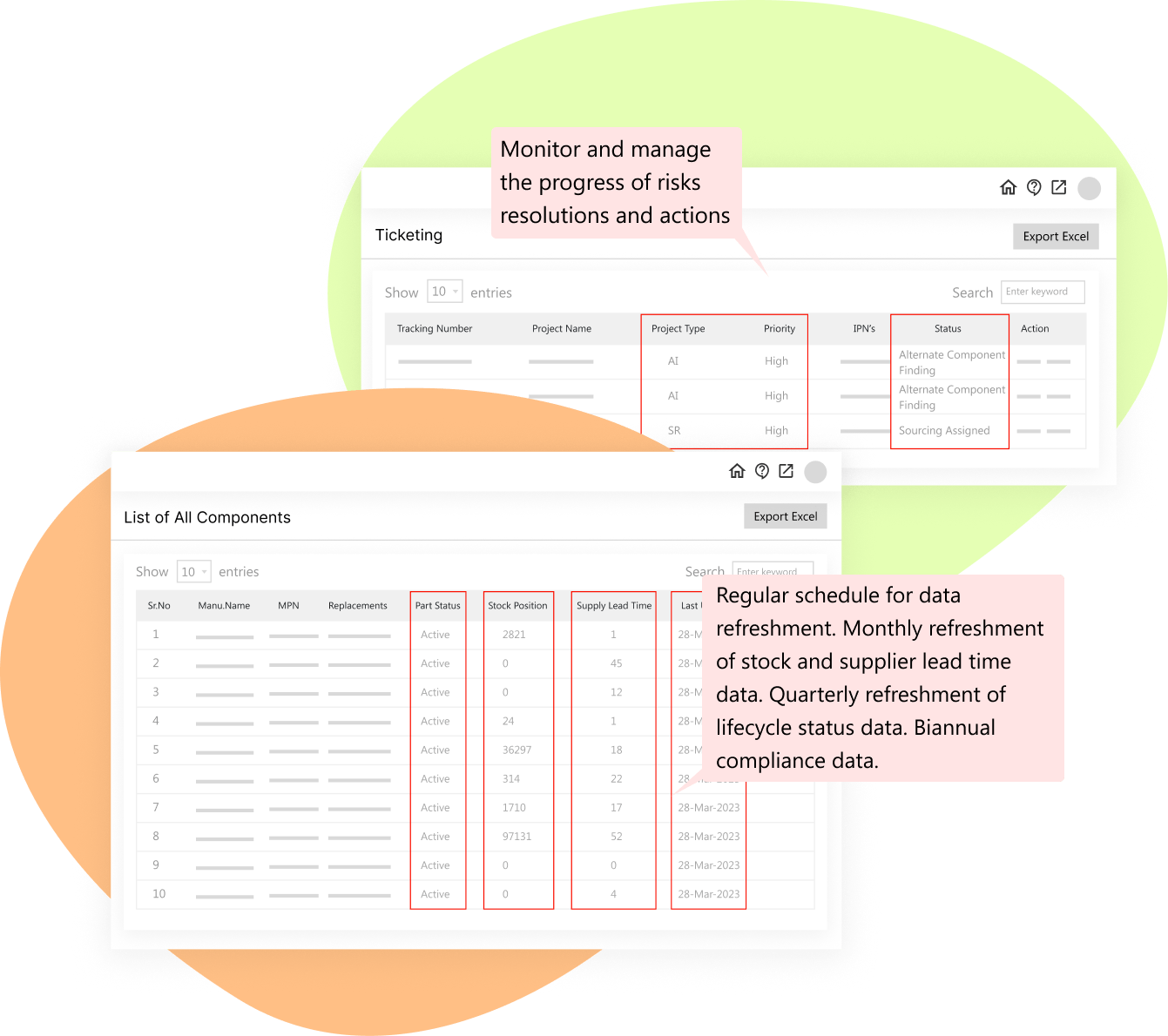

Our application can help engineering and R&D professionals to plan and implement risk mitigation strategies based on the analysis of BoM risks and cross-functional collaboration.

Our application aids Engineering and R&D professionals in Obsolescence analysis, enabling them to identify potential obsolescence and or environmental compliance concerns with components.

By proactively identifying and addressing potential risks, our application can help engineering and R&D professionals to improve their product development process, reduce the risk of supply chain disruptions, and minimize time-to-market.

Our application can enable engineering and R&D professionals to collaborate with other teams, such as supply chain, procurement, quality and compliance, to manage risks throughout the product lifecycle.

Why iLenSys Obsolescence Manager for Sourcing and Procurement?

For those involved in sourcing and procurement our Obsolescence Manager and proactive obsolescence management SaaS application is ideal.

Optimize sourcing strategies, achieve cost savings, and mitigate supply chain disruption risks.

Mitigate supply chain disruption risks and ensure continuity of supply for critical components.

Manage product lifecycle and ensure continuity of supply for critical components.

Manage parts obsolescence risk, optimize sourcing strategies, and improve overall supply chain performance.

Ensure parts availability throughout production run and mitigate supply chain disruption risks.

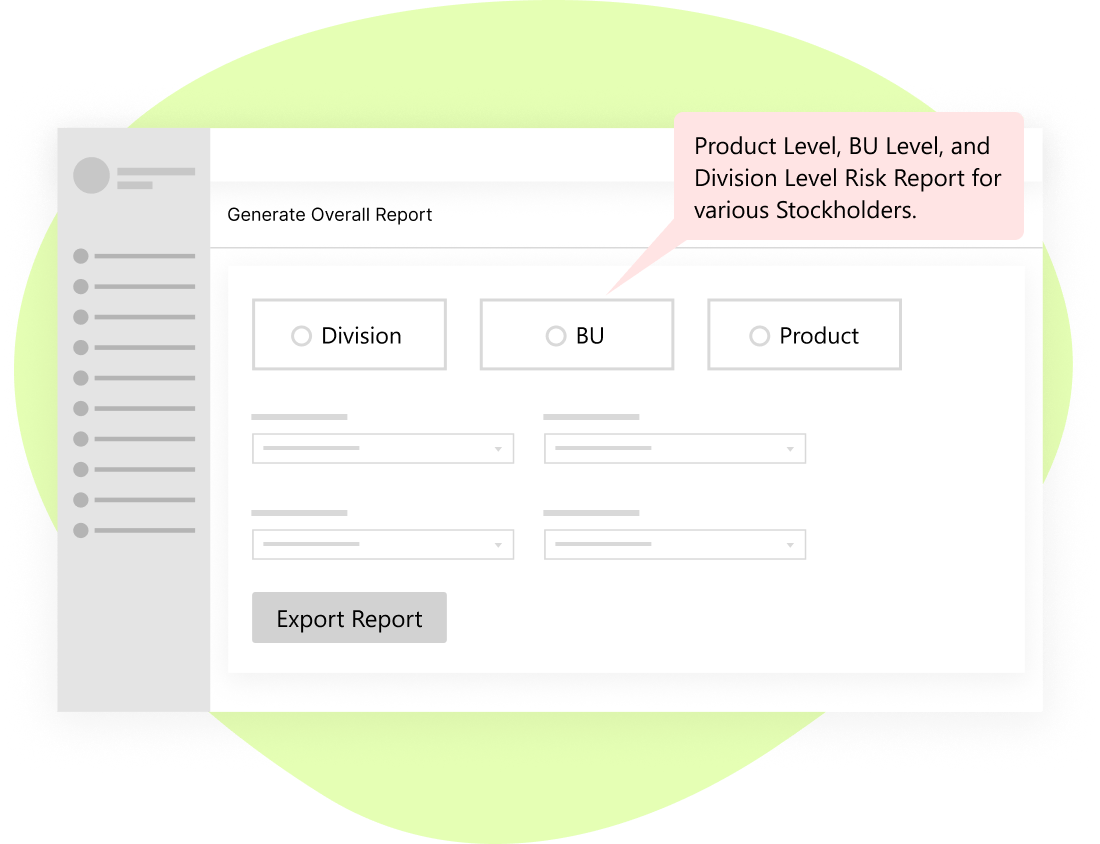

Why iLenSys Obsolescence Manager for Large Organizations?

For large organizations seeking to streamline their electronic component procurement process and mitigate risks associated with parts obsolescence.

Reduce the cost and complexity of managing parts obsolescence and supply chain risks. Improved visibility of components used across business units and increases the efficiency in identifying potential alternates. The amount of time needed to identify alternative parts can be decreased by 25%. This also means that for a quarter of the time, there is no need to search for alternative parts on the open market. For 25% of the time, the implementation can be significantly faster as the alternative parts had already been qualified in other BoMs.