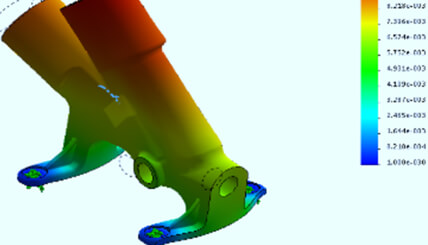

End to End Engineering Services

Our offerings range from New Product Development to detailed design engineering of Mechanical, Electro Mechanical, Industrial Automation to Embedded Design.

Get Started View Services

Elevate Compliance with Our SaaS Solution

Efficiently Manage Product Compliance for Your Products

Request Demo Explore Product

Boost Business with BoM Risk Management

Mitigate Risks and Optimize Bill of Materials with Our Powerful SaaS Tool

Request Demo Explore Product